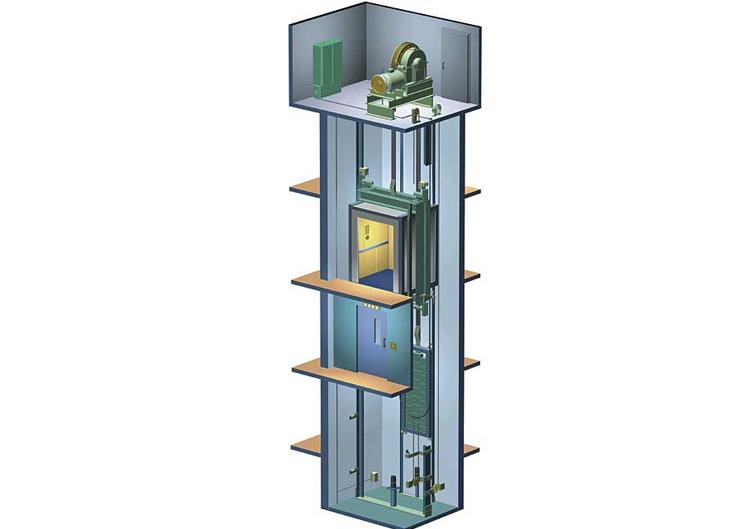

Machine-roomless lifts (MRLs)

MRLs are a type of traction elevators that do not have a machine room on the top of the hoistway. Instead, the traction hoisting machine is located on the top side wall of the hoistway or on the bottom of the hoistway. The motor is installed with a permanent magnet and works with Variable Voltage Variable Frequency drive. Some hoisting machines use gearless synchronous motors instead of conventional induction motors.

Advantages:

- MRLs take up less space in a building since no machine room is required.

- MRLs consume 30% to 80% less power while running than most other types of elevator systems. The power feeders for the MRL are also significantly reduced due to the more efficient design and the counter-balancing provided with traction equipment.

- MRL installations require fewer construction materials and less work time: No well holes to be drilled; no pits to be waterproofed; no requirement for a structural machine- room slab.

- MRLs require significantly less on-site service time than older elevator systems.

- Effective for high load requirements such as freight elevators

- Lowest cost down speed amongst all elevators as gravity is utilized as the motive force.

- No hydraulic oil used – Currently, there are some environmental concerns with oil usage and possible oil seepage or spills, especially in elevators with in-ground jacks.

Disadvantages:

- MRLs have significantly higher standby power requirements than many other elevator systems. (They use more power when not in use.)

- MRLs are more difficult and costly to service than almost all other conventional elevator systems

- Higher repair costs – Due to part availability, repair time could be longer and more expensive. Also, many components must be refurbished or repaired at the manufacturer. Parts for MRLs are usually quite expensive and not as readily available as the parts for older elevator designs.

- MRLs are more expensive and take longer to install than hydraulic elevators for low rise applications

- Most MRLs have a lot of proprietary parts, so the choice of maintaining contractors is usually limited to the installing contractor

Machine Room Lifts.

In commercial applications, the use of higher voltage and required dedicated machine room leaves the fact that at least 25 sq. ft. valuable space is needed for the elevator equipment. With overhead machinery and traction elevators (and in some cases even hydraulic) the machine room can simply be located above the elevator hoistway as long as there is proper access to it and enough room for it.

They do not have the advantages of Machine Room-less lifts

Hi,

your article helps me a lot of elevator concepts.

steady bom bibi

Hey,

My name is Bonny and I’m an elevator practitioners in Delfar from China.

I came across your blog and really like what you’re publishing. As a means to help each other grow our practices and brands, would you be up to do a post exchange (I write for your blog, you write for mine)?

If you don’t have time to write a post, I’d still love the opportunity to contribute to yours.

Here’s a recent example of an article I wrote:

• https://www.delfarelevator.com/top-elevator-company-in-india.html

• https://www.delfarelevator.com/top-10-elevator-companies-in-china.html

• https://www.delfarelevator.com/home-elevator-cost.html

I could also write something more conversational in tone. Let me know your thoughts. Have a great day!

Here is my email: baosm@lanmigo.com. Looking forward to your reply

I’d better like to find a detailed, dimentioned dramwing of the two types of passenger lifts – conventional (with M/room and MRL – say from rooftop when the lift ends on the roof itself